|

Design & Engineering |

|

|

|

Contact EM

Tel: +86 755 2972 2355

Fax: +86 755 2972 2356

E-mail: sales@exceedmold.com |

|

|

|

Hot Search: plastic moulds china, plastic moulding companies china, mold makers china, china mould maker, quality plastic moulds china, injection molded plastic parts china, injection molds china, plastic injection mould china, household molds china, household plastic mould china, plastic auto moulds china, plastic parts china, rapid tools china, plastic molds china, china mould news, moule plastique, moldes de plasticos, molde injeção fabricante, formverktyg, fabbrica stampi plastica, china mould factory, china mould manufacturer, china mould supplier, china mould company, plastic injection mould factory china, china plastic injection mould manufacturer, china plastic injection mould supplier, china plastic injection mould company, china plastic mold factory, china injection mold manufacturer, china toolmaker, china plastic injection molding factory, china plastic injection molding supplier, china auto parts molding factory, china plastic parts production factory, china plastic parts production supplier, china auto mould factory, china automotive mold factory, plastic products molding company china

|

|

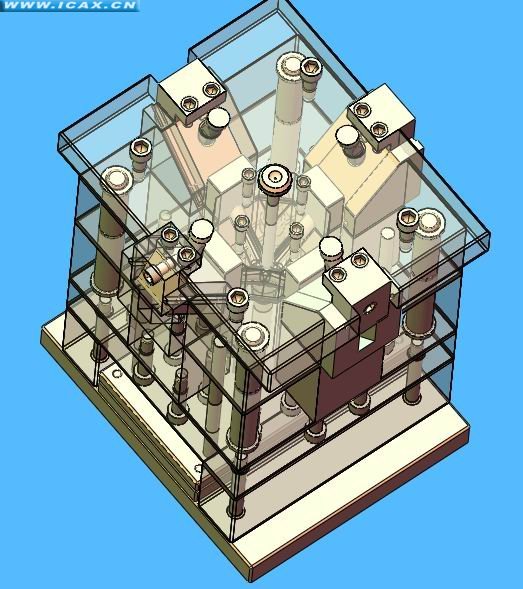

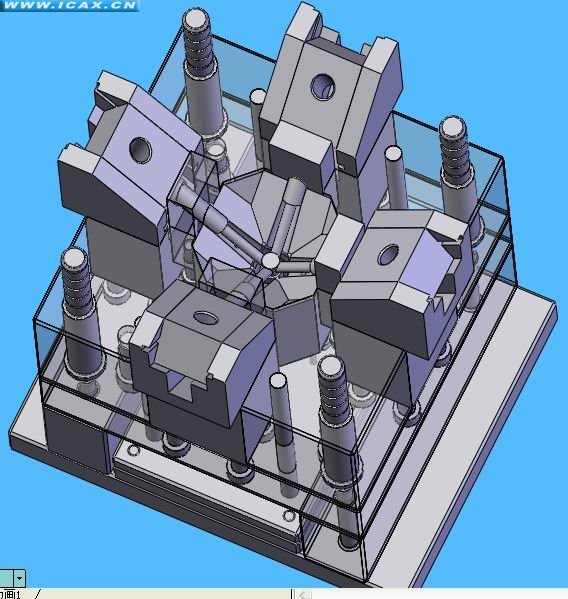

Engineering and Project Management

We provide a wide range of services to help clients with all of the front-end work that goes into a product before actual production begins. Some of those services include preliminary design, material selection, pricing, mold design, evaluation and procurement, CAD/CAM, surface modeling, and communication with the customer's engineering department. For each part we manufacture we will do the DFM study and mold flow analysis which will improve and support the plastic moulds structure design.

We bring you a combination of the best resources available; high technology equipment, quality workmanship, and program management and product development techniques that are flexible enough to meet the needs of your special requirements that can assist the molder or worker and save time and cost.

Project Management

Project management is the key to the success and quality of the products A Project Engineer who has rich knowledge in tooling and injection molding is appointed for each project. All of them have a good command of English.

The project engineers will be responsible to follow up tooling schedule and timely report to the customer on any issues and progress of the project he is handling. The project engineer also guarantees that customer's technical requirement is followed.

Project Management Objectives

- On Time Delivery

- Assuring customer's project is produced to customer's standards and requests

- Anything communicated in a timely and clear way

- Complete project management and support from concept to final part inspection and approval.

plastic moulds China, plastic moulding companies China, mold makers China

Exceed Mold Standards:

Mold Steel: |

ASSAB(Sweden), DAIDO(Japan),FINKL(America),AUBERT & DUVAL(France), Thyssen(Germany), LKM (China) |

Mold Base: |

DME, HASCO, FUTABA, LKM. |

Hot Runner: |

MOULD MASTER, SYNVENTIVE, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY |

Standard Parts: |

DME, HASCO, NEAREST ANSI STANDARD, NEAREST DIN STANDARD, LKM |

Texture: |

Mold-tech, VDI 3400, Yick Sang, Tanazawa etc |

Software

Our engineer mainly used the following software:

Pro/ENGINEER

SolidWorks

AutoCAD

MoldFlow

MasterCAM

Unigraphics

CimatronNC

Surfcam

CATIA

|

|

|

|

| |

|